Our Products

Services

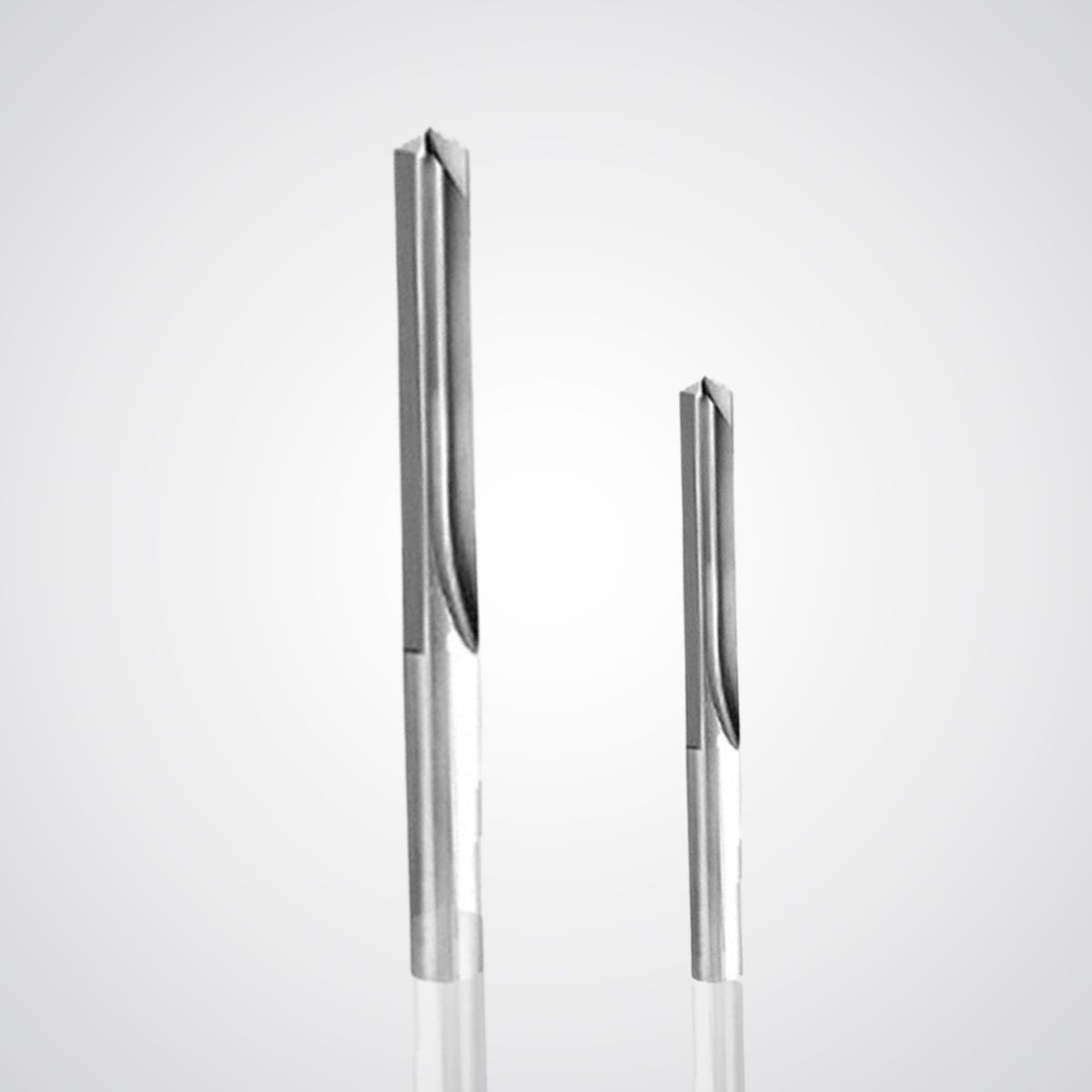

Regrinding and Tool Reconditioning

To extend the life of your carbide tools, we offer professional regrinding and tool reconditioning services. Our team uses advanced grinding techniques to restore your tools to their original performance levels, helping you maximize your investment and reduce operational costs. With precision sharpening and careful inspection, we ensure your reconditioned tools maintain high efficiency.

Re-Coating

Our advanced coating services enhance the durability and performance of your carbide tools. We offer a variety of coatings, including PVD and CVD, to improve wear resistance, reduce friction, and increase tool life. Our coatings are designed to withstand high-speed machining and tough materials, ensuring consistent and reliable performance.

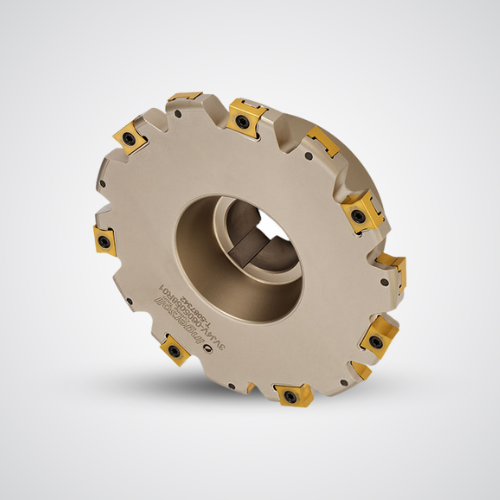

Custom Carbide Tool Design & Manufacturing

We specialize in creating custom carbide tools tailored to your specific machining requirements. Our expert engineers work closely with you to design and manufacture bespoke tooling solutions that optimize performance, reduce downtime, and improve productivity. Whether you need specialized end mills, drills, or inserts, we deliver tools designed to meet your exact specifications.

Prototyping & Tool Testing

We provide prototyping services to help you test and validate custom carbide tools before full-scale production. This ensures that your tools are optimized for performance and durability in your unique application. By conducting thorough testing, we guarantee that our solutions meet your performance expectations before they are put into production.

Precision Tool Grinding

Our advanced grinding technology delivers superior accuracy, improving tool performance and extending tool life. we ensure your tools are sharpened to exact specifications, enhancing performance and longevity. Our precision grinding enhances efficiency and reduces operational downtime for custom geometries or standard tools.

Machines

Industries Served

Aerospace Industry

Automobile & Automotive Industry

Medical Equipment Industry

Energy & Power Generation

Oil and Gas Industry

Die and Moulding Industry

Electronics Equipment Industry

Power Generating Industry

Know More

General Engineering & Manufacturing

Heavy Engineering

Frequently Asked Questions (FAQ)

How do I know which tool is right for my project?

The best tool depends on the task and material you’re working with. Check our product descriptions and guides to see tool recommendations. You can also contact our support team for personalized assistance.

Do your tools come with instructions?

Yes, most of our tools come with an instruction manual that includes assembly, operation, and maintenance information. Some tools also have video tutorials available on our website or YouTube channel.

What materials are your tools made of?

Our tools are crafted from high-quality materials, including hardened steel, stainless steel, and durable plastics, to ensure long-lasting performance. Specific materials vary by tool and are noted in the product descriptions.

How should I maintain and care for my tools?

To keep your tools in top condition, clean them after each use, store them in a dry place, and regularly inspect for wear. Some tools may require lubrication or sharpening. Refer to the user manual for specific care instructions.

How can I stay safe while using your tools?

Safety is our top priority. We recommend wearing protective gear, such as gloves, goggles, and hearing protection, and always following the usage instructions in the manual. Never use a tool for anything other than its intended purpose.